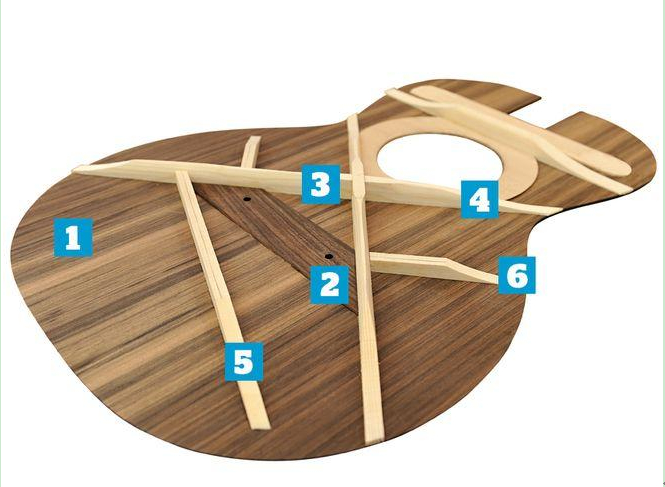

Acoustic Guitar Internal Structure -The Construction of Top

The Top: The internal structure of the guitar top is equivalent to a speaker, which is divergent.

1.The soundboard: top

The role of the top is to transmit real-time dynamics of the strings through the air.

“When choosing a panel for making a guitar, the first element is to consider the hardness of the wood. The best choice is a wood-cut vertical cut sheet with a good enough hardness. When this indicator is not enough, you need to increase the thickness of the soundboard. However, the greater the thickness of the soundboard, the less responsive the response and the less sensitive the response to the strings. In contrast, the sound board with a strong hardness and thin thickness has a dynamic response that is timely and agile. The wood obtained from the quarter-saw is the perfect, and the growth angle of the wood ring is best for making guitar. ”

(The standard thickness of the top is 2.5mm)

PS: The picture is a standard version, but in general each factory has its own sound beam design structure, not exactly the same.

2.Bridgeplate

Under the top, the bridge plate is glued to strengthen the structure of the body, which is generally a hard maple. There are drilled holes to carry string-anchored pins. For many years guitar masters have been searching for the best size wood for bridge decks, because very small differences will be fatal to the sound of the guitar. Maple is by far the best material. (Martin tried to use rosewood bridges in 1970 and the results have been used as an example of failure).

3. Forward shifting

The term specifically refers to the X-shaped bracing center moving forward, about 1 inch from the edge of the sound hole. This is the standard location for the center point of the bracing.

4.X-bracing

There are many types of support beams, but the most popular way is the X-shaped support keel. Martin Frederick Martin, the founder of Martin, first used the trapezoidal support beam design used in classical guitars. Later, Martin designed the X-shaped support keel for the gut guitar for the first time. It was not until the 1920s that Martin began to produce steel-string guitars. The internal structure of acoustic guitars began to use X-shaped support bracings. Until today, it is still the most practical and popular acoustic guitar internal support.

5.Tone bars

To support the X bracing, many steel string guitar panels use this ancient support beam design. The reason why it is called the sound bar is that the position and shape of these support beams have a great influence on the vibration of the panel, and further influence the sound of the guitar through the vibration of the panel.

6.Scalloping bracing

Also as a reinforced structure, the high-quality steel-string guitar is a huge pulling force for the balance string, and this part of the structure will be carefully manufactured. At the same time, these support beams can also ensure the free vibration of the panel, rather than being too stiff.

Leave a Reply

You must be logged in to post a comment.